45 MBCA Ductless Unit and the “CP” Error Code

Most ductless products have all of the error codes listed in the installation and service manuals. Error codes listed in

VRF Quality Assurance Manager

Gulf Coast District

Have you ever shown up to a service call on a Carrier/Bryant/WeatherMaker (Midea) ductless system and found it locked out on a P4 or PC04 error code showing on the indoor display? Did the code return after a power cycle? Did the unit attempt to run? This article will help you understand what these codes mean and how to troubleshoot them effectively.

When working on any system, it is important to know the model number. These codes can mean different problems depending on the equipment, and where the error is displayed. In this article, I am referring to the following outdoor models:

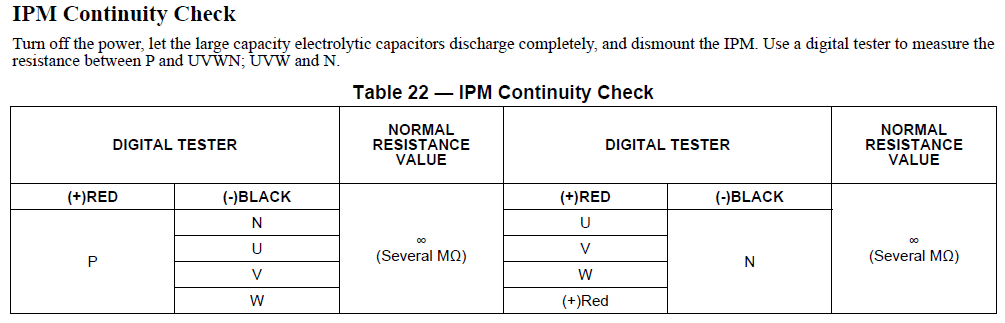

Tips and Tricks: The following diagnostics can also apply to P6 and PC00 codes for IPM Protection

What do these codes mean? P4 and PC04 are Inverter Compressor Drive errors. Even though they sound specific, these codes can be generated from a broad spectrum of component failures and operating issues within the system.

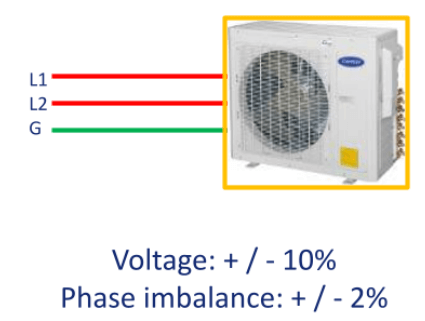

Read L1 to L2. What is the actual line voltage vs the minimum and maximum listed on the data plate? Read each leg to ground. Are they balanced? Check the main breaker, next the disconnect, and then the equipment. Was there any drop or difference in the voltage?

Replacing a part may remedy a symptom, but not necessarily the cause. Dirty power issues can be overlooked when components have failed. If left unchecked, voltage that is too high, too low, or imbalanced can make for recurring issues.

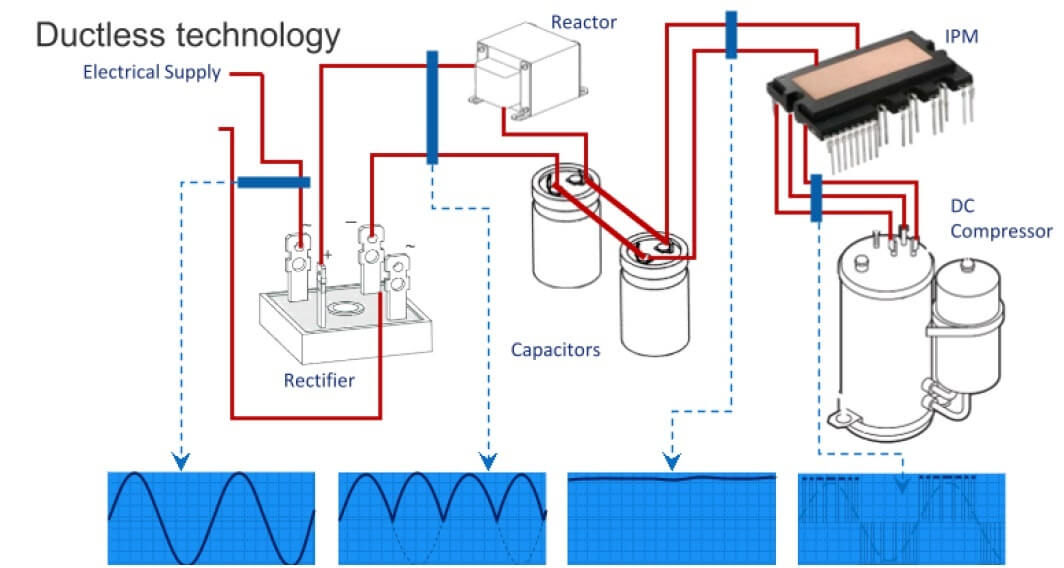

The first stop in the inverter power circuit is the bridge rectifier. Its purpose is to convert the AC line voltage to DC. In essence, it flips the bottom half of the sine wave to the top. The formula for DC output is 1.414 x AC line voltage. Next in the circuit are the reactor and capacitors. These components pull tension on and flatten out the sine wave. Then the IPM (Intelligent Power Module) or IGBT (Insulated Gate Bipolar Transistor) uses this voltage to send precisely controlled frequency to the compressor and DC fan motor(s).

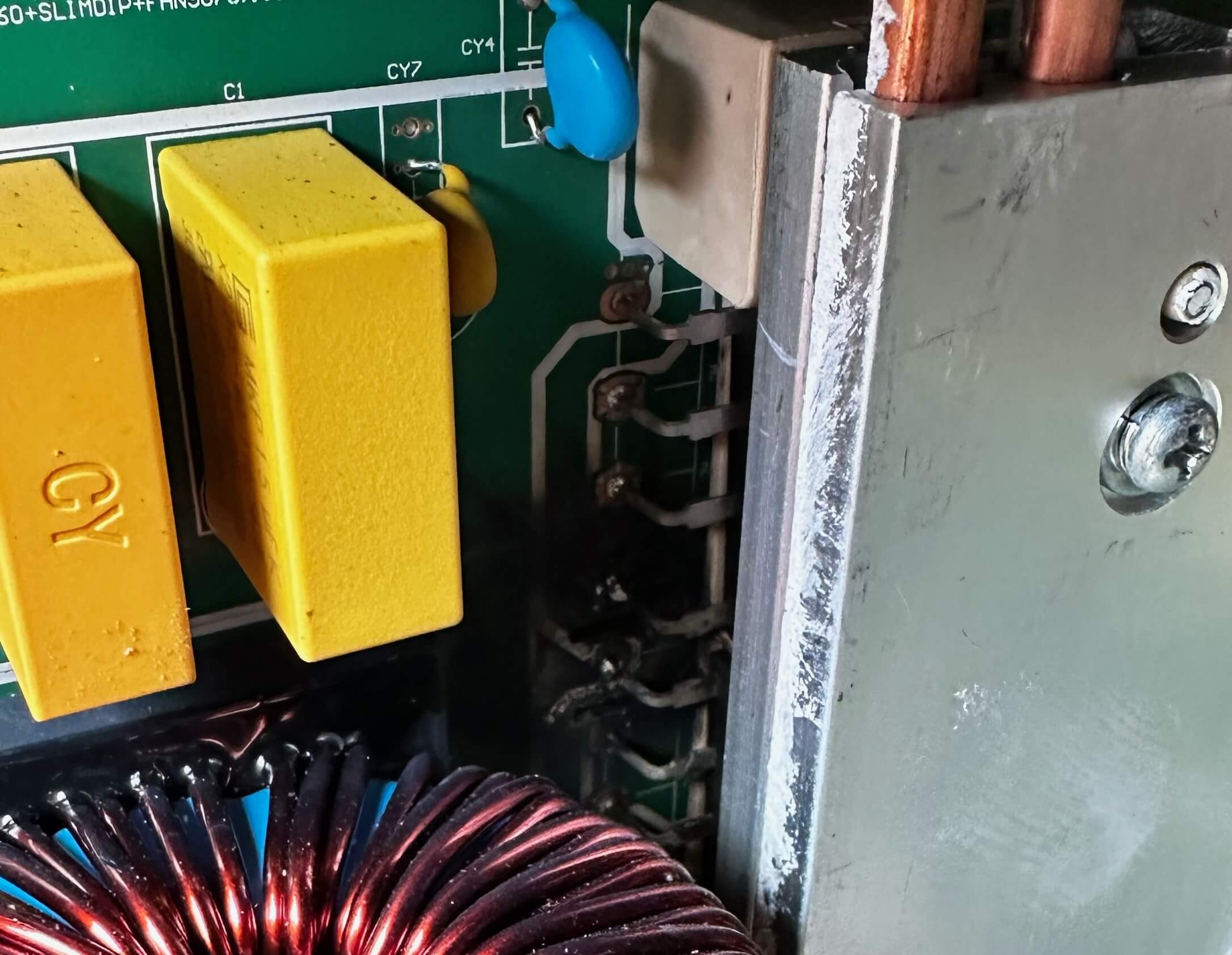

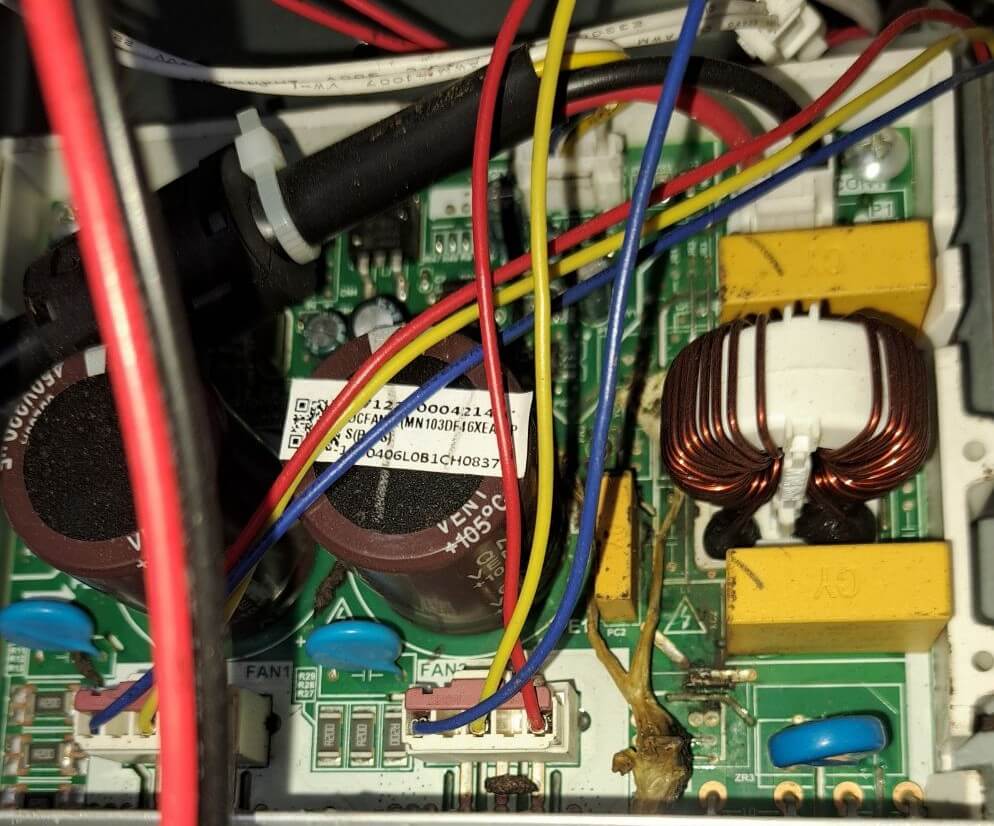

After you have verified a good power supply to the equipment, perform a visual inspection of the wiring and circuitry. Some issues are more obvious than others.

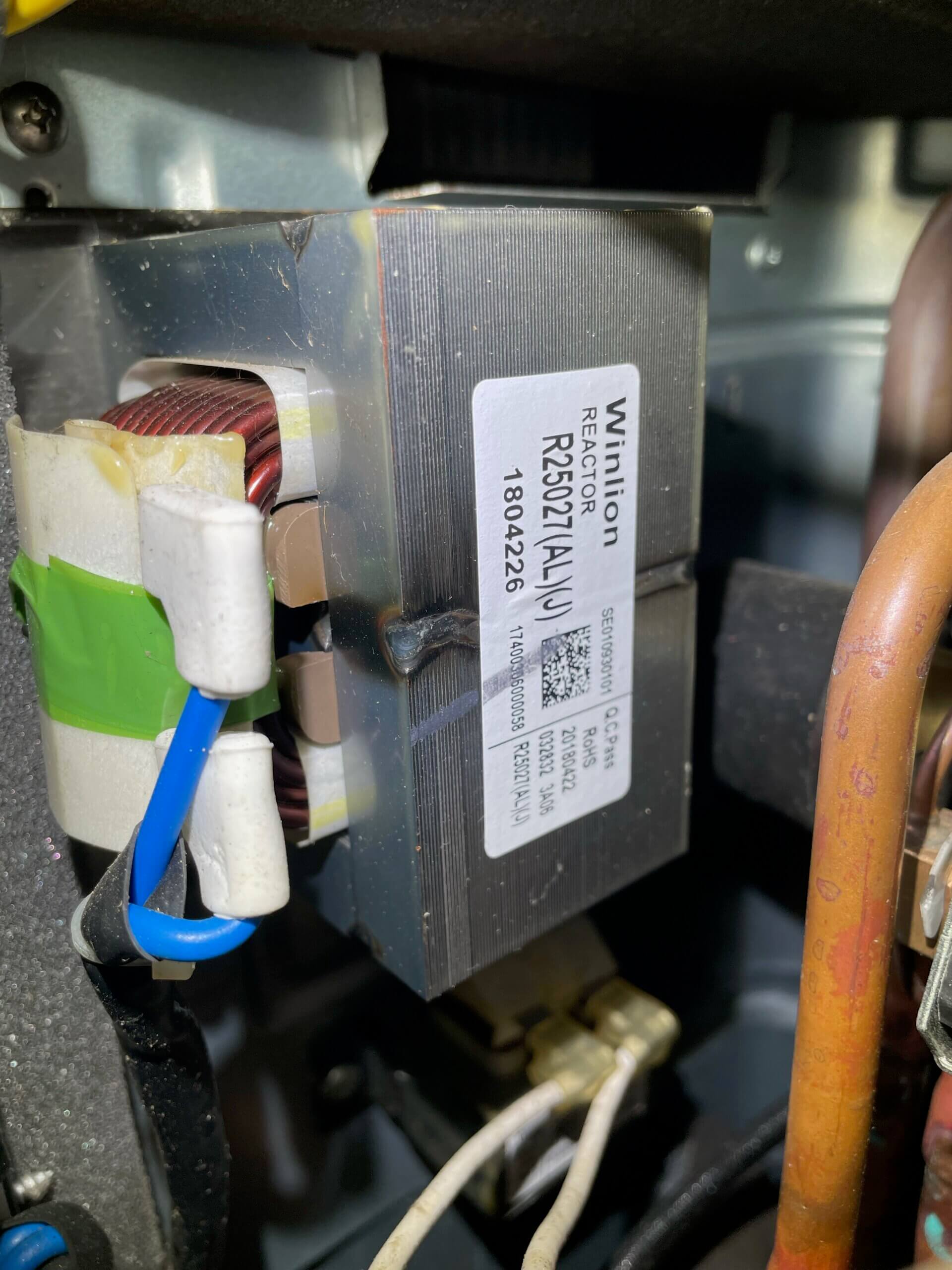

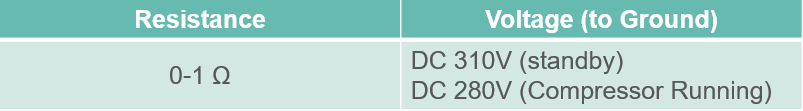

These components are integral to the inverter circuit. Capacitors can usually be found bad on a visual inspection. Failures in reactors are uncommon, and they can be easily overlooked. Reactors should ohm very close to zero resistance. They should never be open or have any continuity to ground.

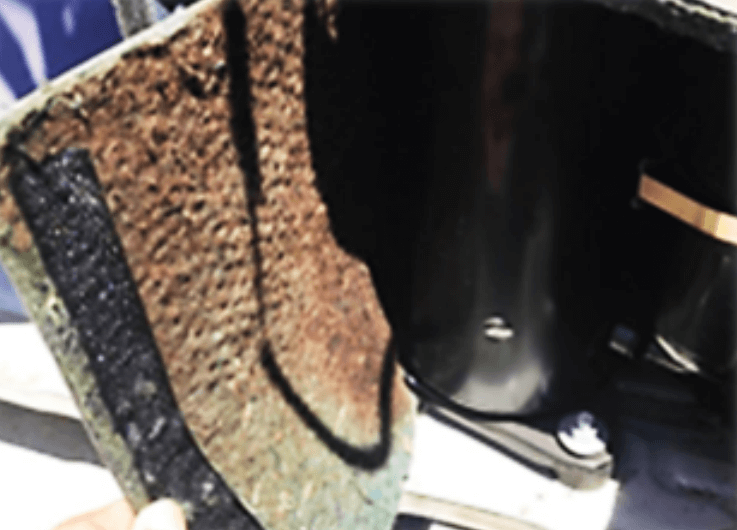

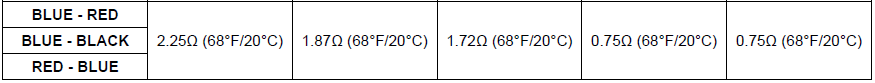

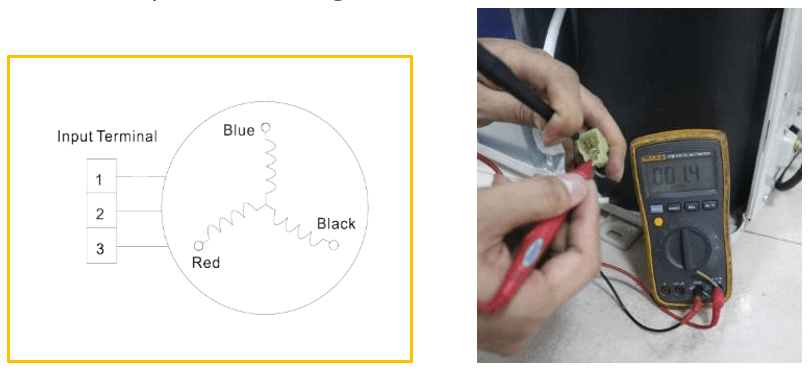

Has the sound blanket turned from green to brown? This is a sure sign it has overheated or possibly become demagnetized. Ohm the compressor windings. Remember, this is a three-phase motor. Your measurements should be balanced and less than 2.25 ohms. Nothing should read open or continuity to ground.

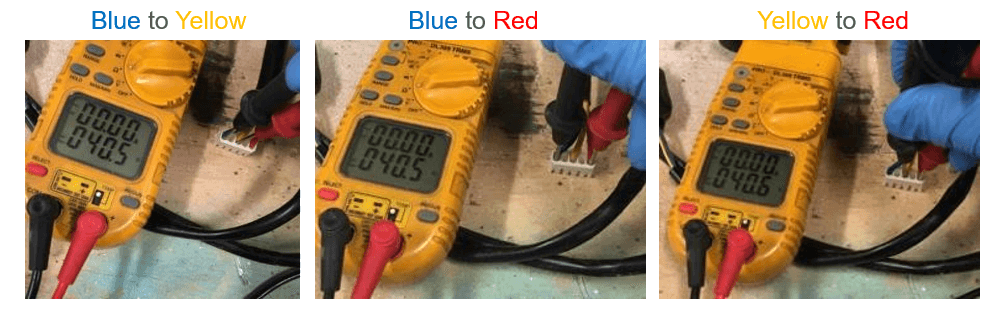

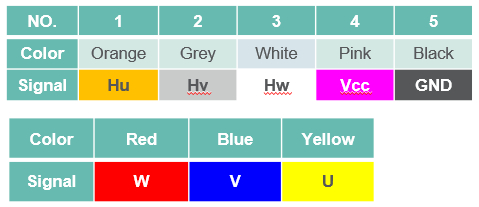

Does it spin freely? If not, then the bearings have failed. If yes, then ohm the windings from the UVW connector. It will be a much higher resistance than the compressor but should still be balanced between any two pins. It should not be open or grounded. On units with two motors, perform the process with each.

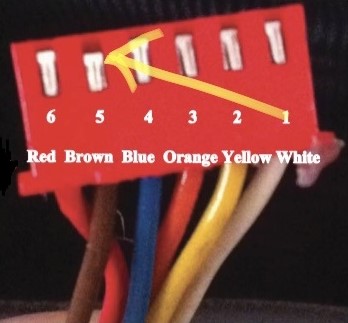

If the fan motor windings read correctly, further investigation may be necessary. Turn on power to the unit. Some motors use feedback for speed recognition. During standby, 5 VDC should always be present on the 4 & 5 pins of the feedback connector.

If it is not present, you have a shorted PC board. If it is present, then progress to the next step. Rotate the fan by hand and measure pins 1 & 5, 2 & 5, and 3 & 5. If any negative voltage is displayed, then replace the motor.

Learning to find all these check points on the back of a control board takes time and experience. Every board is different. If they do not have to be returned for warranty purposes, save your failed parts for practice and study tools.

Bad communication between the main PC and the Inverter can cause a P4 code. Check the wired connectors for poor alignment. This can happen when components are replaced, and someone pulled on the wires instead of the connector. Loose connections can wreak havoc on a communication circuit.

Hopefully, the knowledge from this article will take some of the dread out of diagnosing a unit with these error codes and help you be more efficient when working with ductless products.

Disclaimer: The technical statements, information and recommendations contained herein are believed to be accurate as of the date hereof, but Mingledorff’s does not make representations or warranties, express or implied, as to its accuracy, its completeness, or the results to be obtained. The information is being provided for informational purposes only and is intended for use by persons having adequate skill and expertise regarding the proper selection, use and application of the products and recommendations and at their own risk and discretion.

Most ductless products have all of the error codes listed in the installation and service manuals. Error codes listed in

We have multiple articles about the defrost boards for residential and commercial units on our website and each has addressed

There are several different types of ductless heating and cooling systems. These systems can be combined with various indoor and