It’s important to keep HVAC Tools Calibrated

…and not just for the “by-the-book reasons Here’s why it matters in the real world: Accurate diagnostics – Gauges, thermometers, manometers,

Technical Services Manager

North Georgia District

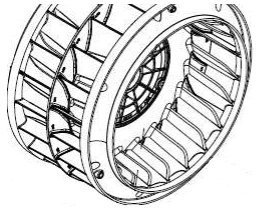

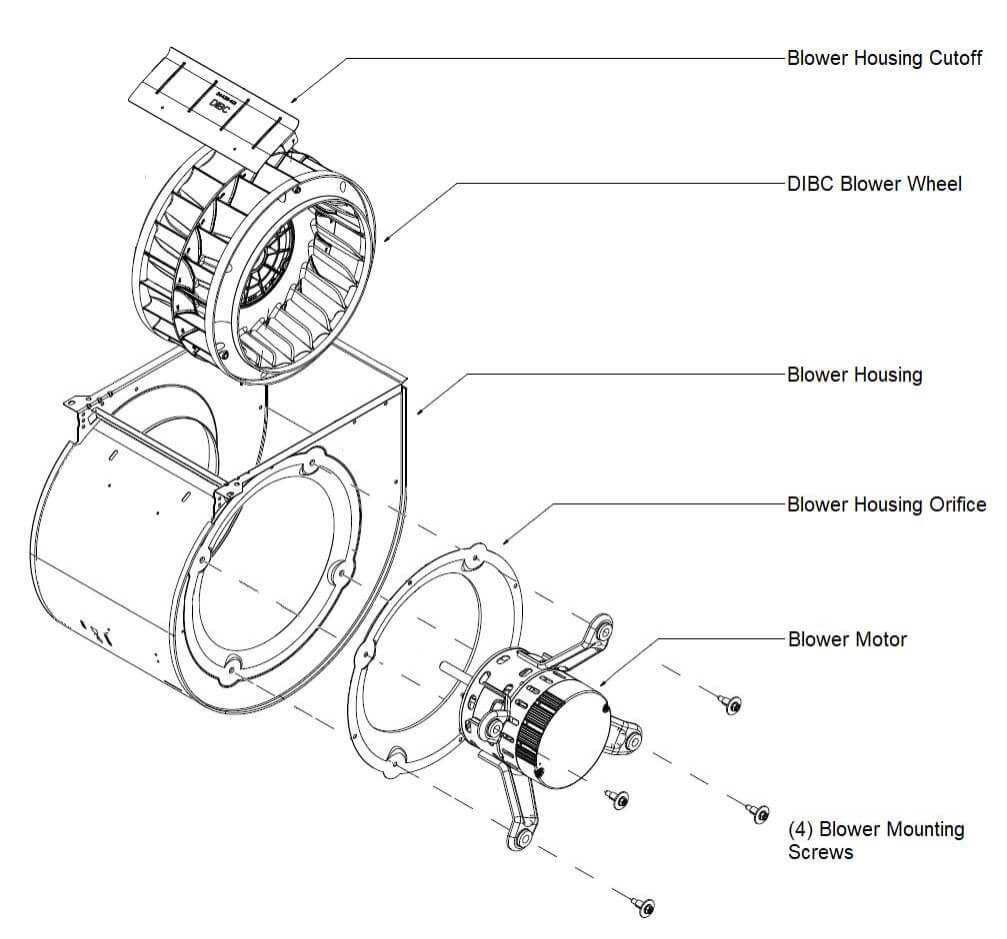

The models listed at the end of this newsletter are designed to meet federal Fan Energy Rating (FER) requirements and are scheduled to be released into production. These furnaces use a dual-inlet backward curve fan wheel. The installation of these wheels into the blower housing and onto the motor shaft during service or replacement varies slightly from current standard field installation practices.

Typical installation of traditional blower wheels requires you to slide the wheel on and center it into the housing. For the new wheel and motor design, the installer, after completing installation of the motor to the housing, will slide the blower wheel to the stop mechanism designed into the flat of the motor shaft per Carrier’s Specifications.

Carrier’s Installation instructions for the blower wheel are as follows as per TIC 2019-0012.

Carrier

59SC5B040E141110

59SC5B060E141112

59TP6B040V141110

59TP6B060V141112

Bryant

915SB30040E14A-A

915SB36060E14A-A

926TB30040E14A-A

926TB36060E14A-A

Payne

PG95ESAA30040AAA

PG95ESAA36060AAA

PG96VTAA30040AAA

PG96VTAA36060AAA

…and not just for the “by-the-book reasons Here’s why it matters in the real world: Accurate diagnostics – Gauges, thermometers, manometers,

This new unit is a noncommunicating variable 5 speed performance line heat pump with InteliSense technology, 19 seer2. Sizes range

When you get a new VFD drive and want to install it and you see that the other one was

We use cookies and other tracking technologies to collect and store information, operate our website, remember your preferences, deliver targeted ads and content, and enhance your experience. You can manage or change your cookie preferences at any time through your browser or device settings. To learn more, including how we collect, use, or disclose your information, please review our Privacy Policy and Terms of Use. By interacting with this cookie banner or accessing the site, you consent to our Privacy Policy and Terms of Use, including the arbitration provision and class action waiver.